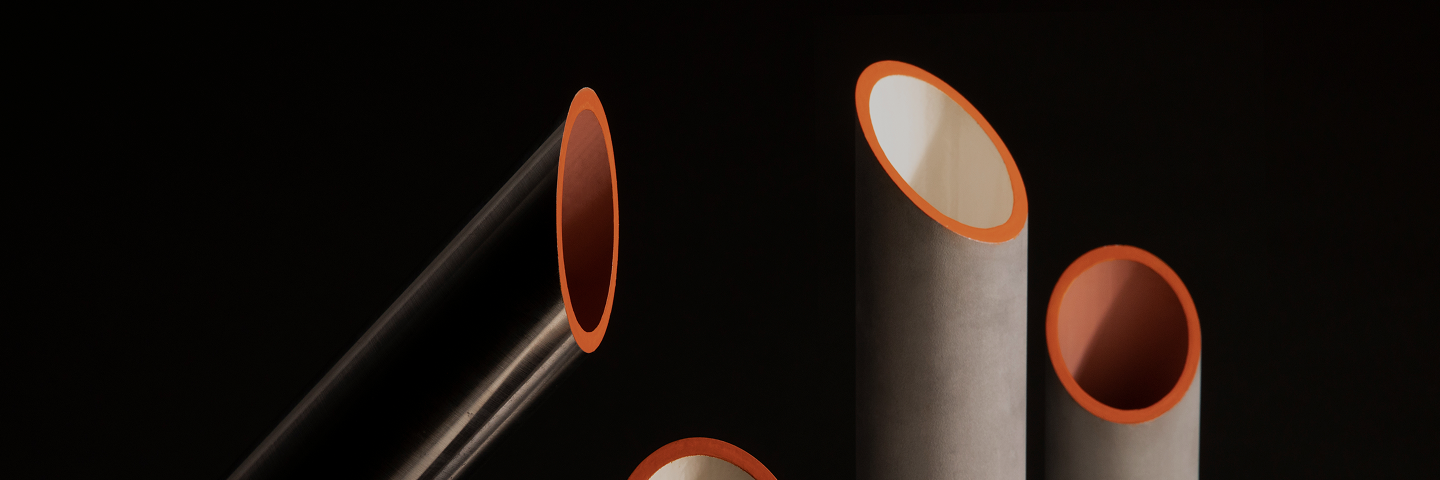

RETHINKING TUBULAR PROTECTION

At Alteriver™, we believe efficiency and sustainability go hand in hand.

In an industry where durability means everything, we develop solutions that not only extend the lifespan of production tubing but also reduce environmental impact.

Our proprietary technologies help oil and gas operators tackle the toughest well integrity challenges, minimising waste and maximising performance.

Solving the Right Problems

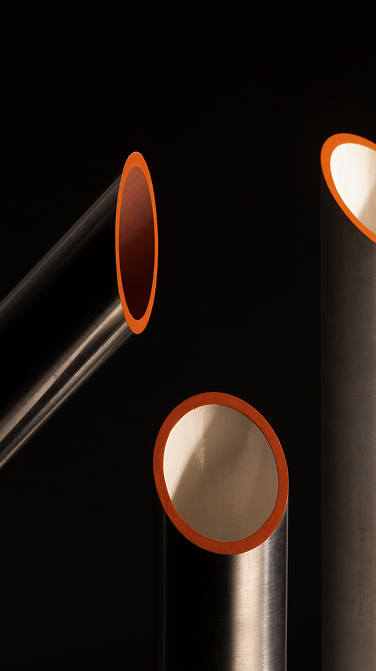

From aggressive corrosion and ARPD buildup to hydrogen embrittlement and washout, Alteriver™’s innovations directly address the biggest threats to production tubing. Using advanced Thermal Diffusion technology, we create corrosion-resistant solutions that outperform traditional coatings and treatments. Our ziPLY and reziPLY product lines deliver field-proven protection, extending the life of tubing and reducing the need for costly interventions.

We offer a full range of well integrity solutions

TDZ Ultra-premium

2 products

Designed and manufactured for complete protection of tubing, including threads and external surfaces

Premium IPC

2 products

Designed to protect tubing in environments with excessive asphalteneresin-paraffin deposits (ARPD) and corrosion

streamer®

1 product

A patented device designed to protect tubing pin ends and internal threads from corrosion and washout in aggressive downhole conditions

A Smarter Approach to Production

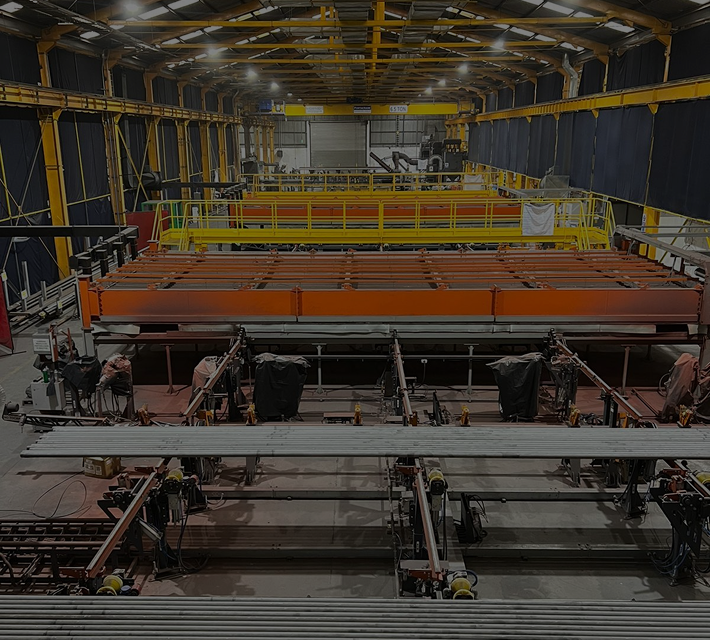

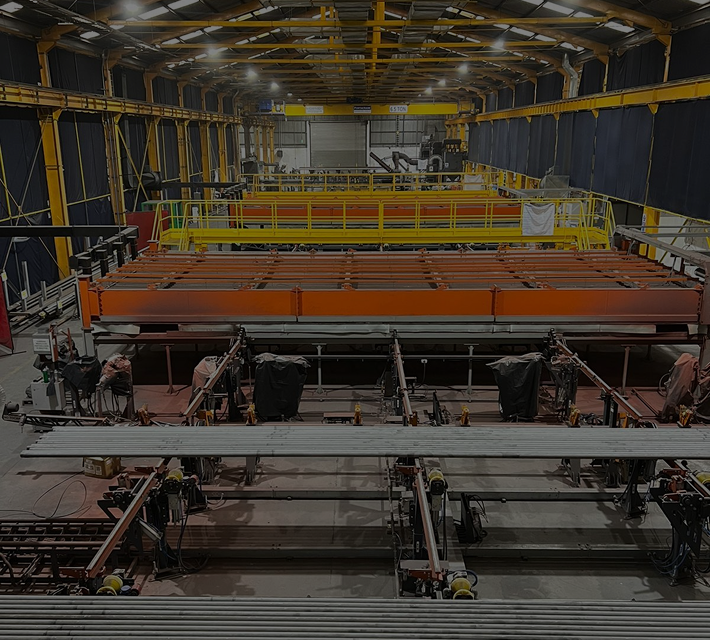

Strategically located in Monterrey, Mexico, our dedicated production facility allows us to maintain strict quality control while ensuring fast, reliable delivery across North America.

We also maintain warehousing in West Texas and Houston to keep inventory close to where it’s needed most. By handling every step of the process in-house, we ensure our customers get products engineered for reliability and built for efficiency.

Engaging with the Industry

We actively participate in industry events, conferences, and exhibitions, sharing insights and innovations with the wider energy community. Keep an eye on our latest updates and upcoming appearances to connect with us in person.

ADIPEC 2025

How, Why and Where Thermal Diffused Properties Work In Oil and Gas

ADIPEC 2024

How, Why and Where Thermal Diffused Properties Work In Oil and Gas

Carbon Capture Technology Expo North America

How, Why and Where Thermal Diffused Properties Work In Oil and Gas

ALTERIVER™ Core Company Capabilities

Protective Coating Formulations

ALTERIVER™ Inc. provides custom manufacturing services for steel pipes and tubing supporting a variety of oilfield applications. The company capabilities include heat treatment and coating of pipes and downhole tubing. The company also specializes in metal heat treating services through the use of thermal diffusion for the application of zinc coatings to metals for use in oil and gas industry.

Custom Manufacturing and Heat Treatment

ALTERIVER™ Inc. provides custom manufacturing services for steel pipes and tubing supporting a variety of oilfield applications. The company capabilities include heat treatment and coating of pipes and downhole tubing. The company also specializes in metal heat treating services through the use of thermal diffusion for the application of zinc coatings to metals for use in oil and gas industry.

Coating Application Services

ALTERIVER™ Inc. offers comprehensive coating application services for a full range of substrates and service environments. Company provides the following coatings to the customers: applying protective coating such as zinc and polymer coating; applying protective coating consisting of zinc, polymers, wear resistance, anti-rust and anti-corrosion substances. There is also offered repairing corrosive and leaking pipes through the application of coating inside of the pipe utilizing a durable epoxy.

Inspection, Testing, and Quality Management

Ensuring product reliability is central to ALTERIVER™ Inc.’s operations. The company conducts inspection, testing, and diagnostic services for downhole tubing, pipelines, and coated components, verifying compliance with industry and certification standards. The company capabilities include quality management services, namely, quality evaluation and analysis. Company also provides quality assurance, and quality control for downhole tubing. Services further include testing, analysis, and evaluation of downhole tubing to assure compliance with industry standards.

Looking Ahead

The energy industry is evolving, and so are we. Our research and development efforts continue to push the boundaries of tubular protection, helping operators adapt to changing demands and sustainability goals. With new challenges come new opportunities, and Alteriver™ is ready to lead the way in well integrity solutions that are both effective and responsible.

Built for Performance Engineered for the Future