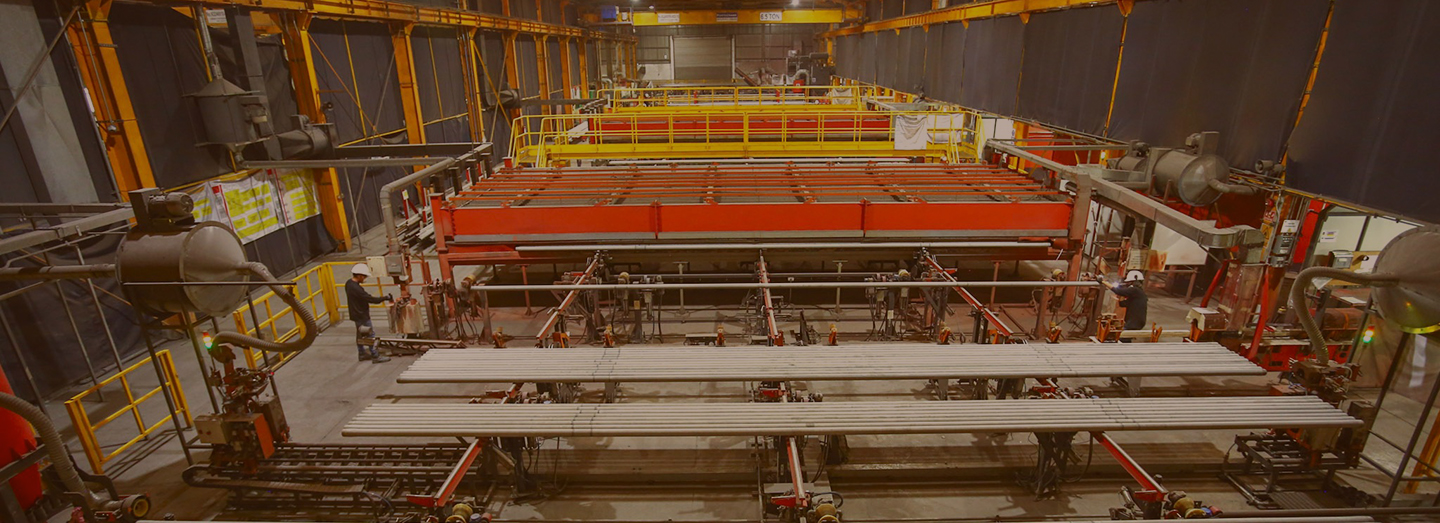

At Alteriver™’s state-of-the-art facility in Monterrey, Mexico, thorough preparation is the absolute foundation for oil and gas production tubing that survives the harshest downhole environments. Inadequate surface preparation leads to catastrophic failures—coating delamination, corrosion breaches, and costly production downtime that can derail entire operations. Incoming steel tubing undergoes rigorous pre-inspection by qualified specialists, ensuring only flawless material advances. Alteriver™’s unwavering attention to detail exceeds industry standards, eliminating defects and creating an impeccable substrate for thermal zinc diffusion and Internal Plastic Coatings (IPC).

The process advances with extensive cleaning to remove contaminants, followed by Alteriver™’s proprietary dual-axis shotblasting system. This advanced, PLC-controlled technology delivers a uniform surface tecture far superior to conventional methods, optimizing adhesion and ensuring a strong bond, thus avoiding premature failures. Every step reflects Alteriver™’s relentless precision, setting a benchmark above industry norms for reliability and performance in extreme conditions.

This meticulous preparation is the cornerstone of Alteriver™’s engineering excellence, transforming raw steel into tubing that outperforms in the most demanding applications—delivering peace of mind where others fall short.